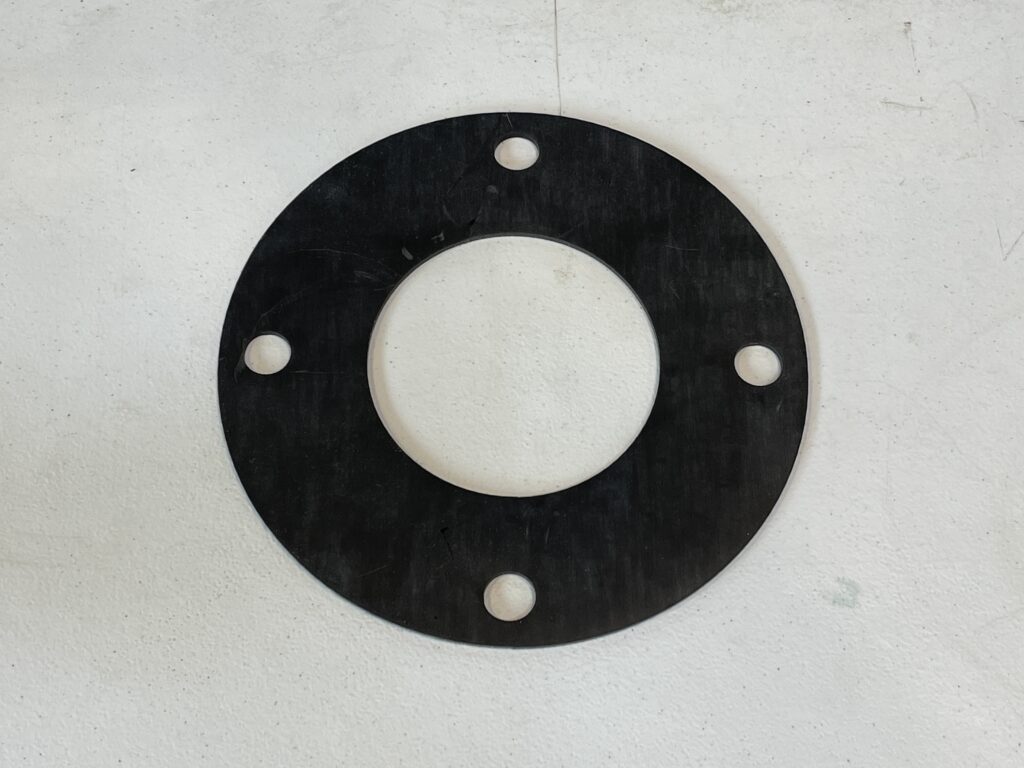

EPDM GASKETS

EPDM (Ethylene Propylene Diene Monomer) gaskets are made from synthetic rubber and are known for their excellent weather and ozone resistance. EPDM rubber’s temperature resistance is another great benefit, offering a solid temperature range of as low as -60° Fahrenheit and up to 300° Fahrenheit.

EPDM rubber is not particularly well know for use in applications where there is direct contact with petroleum-based products as it has poor resistance to oils, greases, and fuels.

Common applications for EPDM gaskets

- Automotive Industry: EPDM gaskets are widely used in the automotive industry for sealing applications in engines, transmissions, and exhaust systems.

- Aerospace Industry: EPDM gaskets are used in the aerospace industry for sealing applications in engines, fuel systems, and hydraulic systems.

- Construction Industry: EPDM gaskets are used in the construction industry for sealing applications in doors, windows, and roofing systems.

- Electrical Industry: EPDM gaskets are used in the electrical industry for sealing applications in electrical enclosures and transformers.

- Food and Beverage Industry: EPDM gaskets are used in the food and beverage industry for sealing applications in tanks, pipes, and valves.

- HVAC Industry: EPDM gaskets are used in the HVAC industry for sealing applications in ductwork, vents, and air handlers.

- Medical Industry: EPDM gaskets are used in the medical industry for sealing applications in medical devices, surgical instruments, and hospital equipment.

- Oil and Gas Industry: EPDM gaskets are used in the oil and gas industry for sealing applications in pipelines, valves, and pumps although typically do not make direct contact with petroleum products or are closely monitored on a replacement schedule.

- Pharmaceutical Industry: EPDM gaskets are used in the pharmaceutical industry for sealing applications in equipment used in the manufacturing of drugs and medicines.

- Water Treatment Industry: EPDM gaskets are used in the water treatment industry for sealing applications in pipes, valves, and tanks used in water treatment plants.

OUR CAPABILITIES

Whether it be in small test batches with one of our CNC Knife Cutting Machines or with large scale production on one of our premium Die Cutting Machines, American Cutting Solutions is uniquely equipped to supercharge your production, converting, and supply chain process.